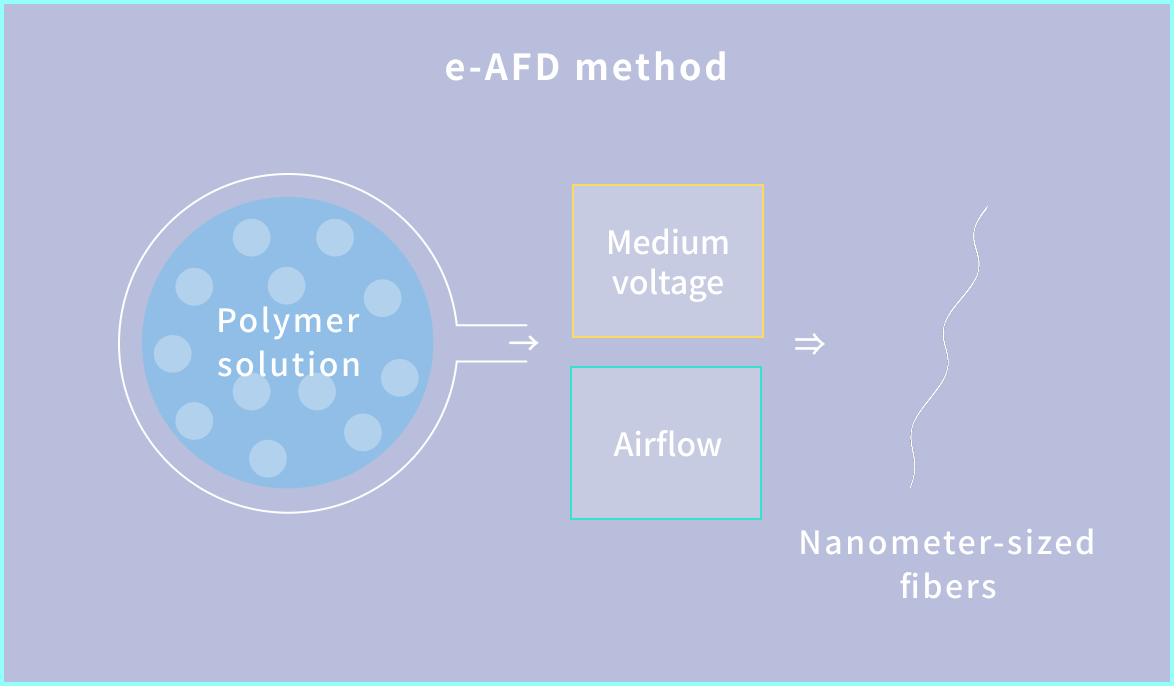

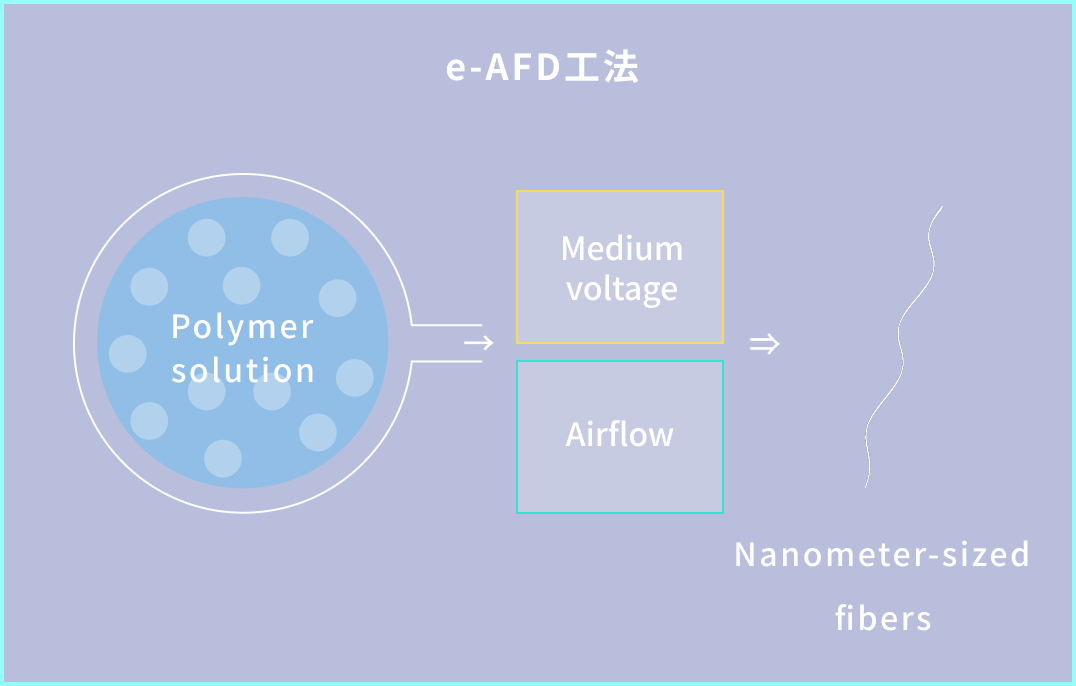

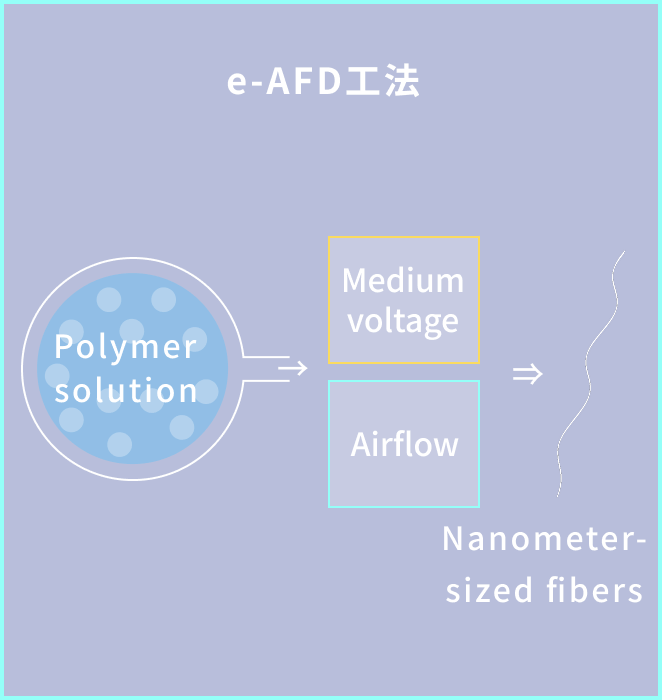

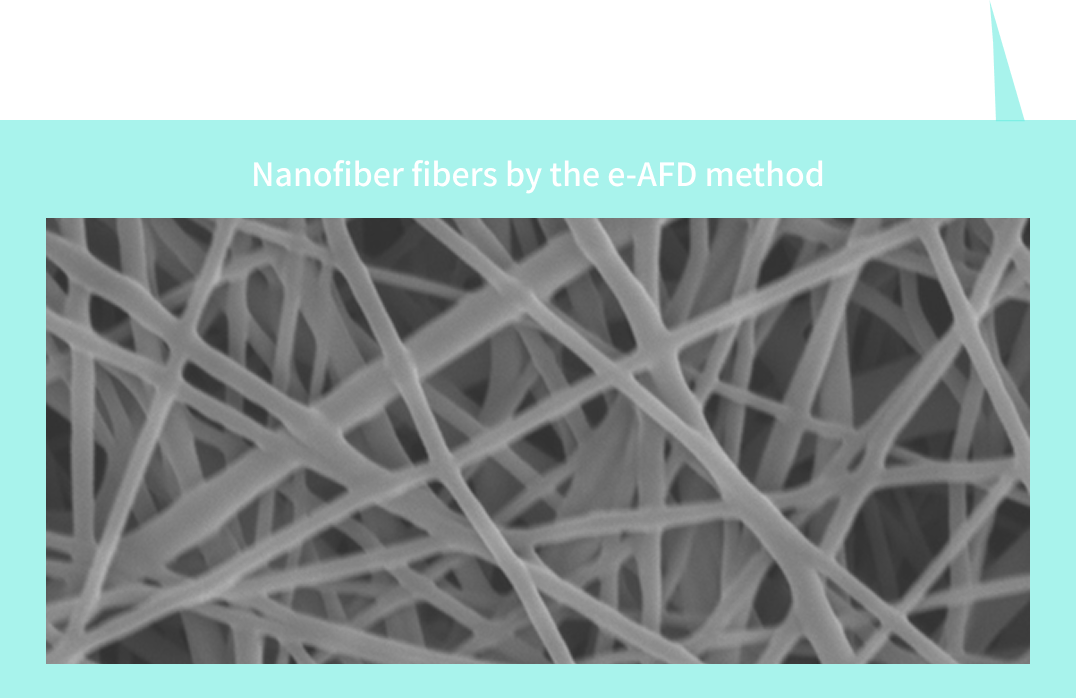

e-AFD method, which uses an electric field for enhanced stability and safety

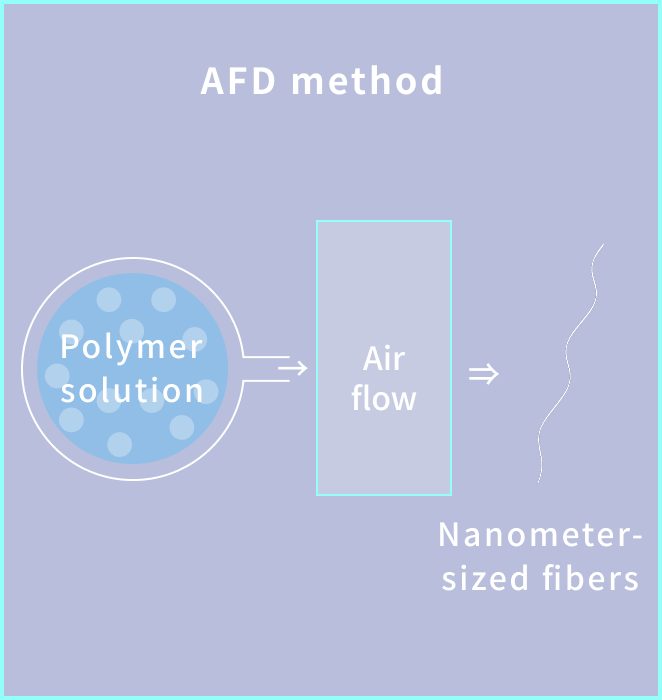

The AFD method has a drawback in that the fibers dry due to the force of the airflow, resulting in weak adhesion between the nanofibers. To address this, Technical Fine developed a new technology called the e-AFD method (Electro Air Fiber Deposition). By applying an electric field within a safe range, the fibers are prevented from drying before collection, allowing for stronger adhesion between the nanofibers.

Advantages of the e-AFD method

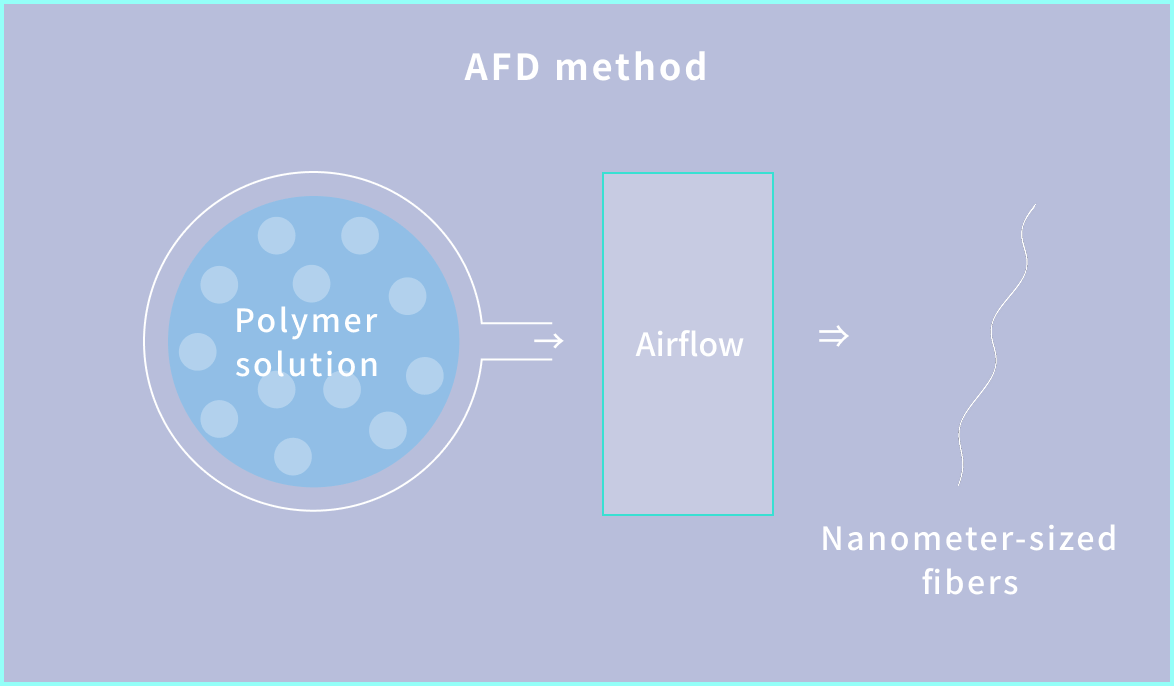

The AFD method is effective for nanofibers, but since each individual fiber dries separately, it has some drawbacks in terms of handleability when used in sheet form. Nanofiber sheets produced by the e-AFD method can improve characteristics such as handleability and high-density formation, making it more versatile for various applications.

Improved handleability

Improves the difficulty in handling nanofiber sheets, a challenge with the AFD method, enabling the production of more manageable sheets.

Generation of high-density sheets

The fibers are evenly arranged, minimizing gaps. Additionally, there is technology to arrange the fibers finely and densely in a uniform manner.

Adaptability according to applications

Compared to the high-speed generation and mass production capability of the AFD method, the e-AFD method allows for generation focused on functionality and practicality.