About Nanofiber

What is Nanofiber?

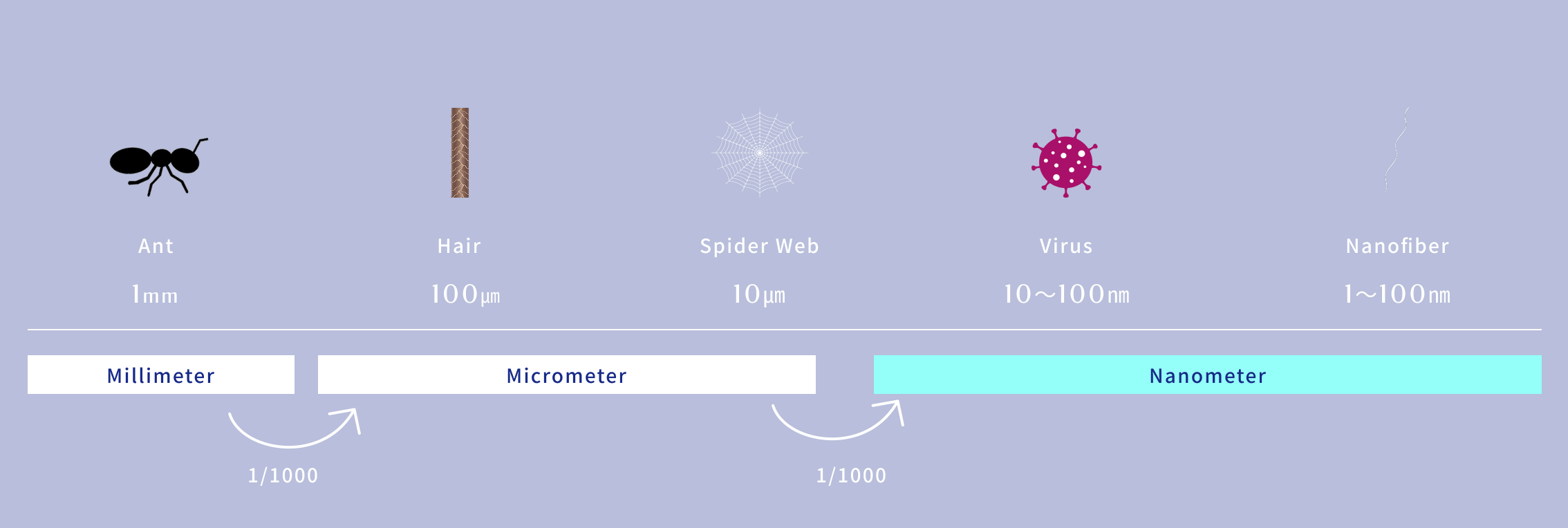

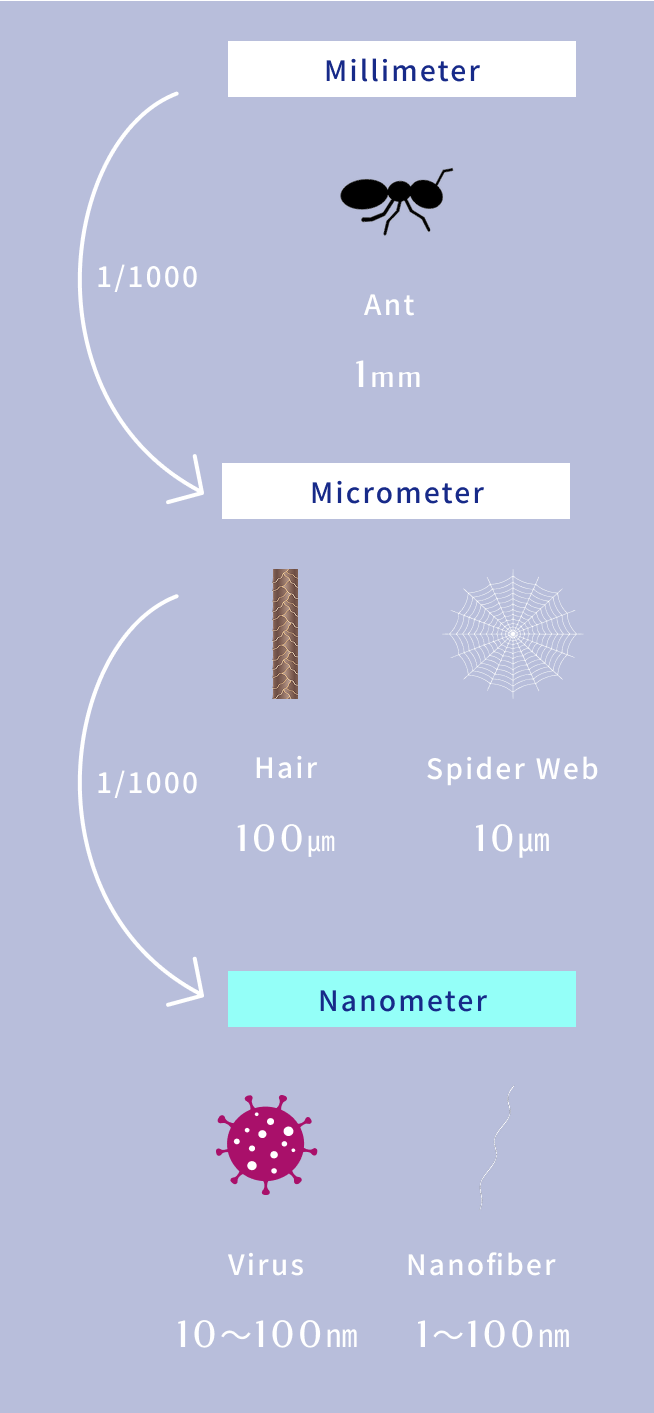

Nanofibers are extremely thin fibers, referring to fibers with a diameter (or one side) within the range of 999 nanometers.

One nanometer is one-millionth of a millimeter, making it an incredibly small unit. Due to their ultra-fine structure, nanofibers exhibit a high surface area and excellent filtration performance.

As a result, they possess superior physical properties that conventional fiber materials cannot achieve. This technology enables the development of water-repellent and oil-resistant materials while providing alternatives without the use of harmful chemicals.

Advantages of Nanofibers

Ultra-High Specific Surface Area

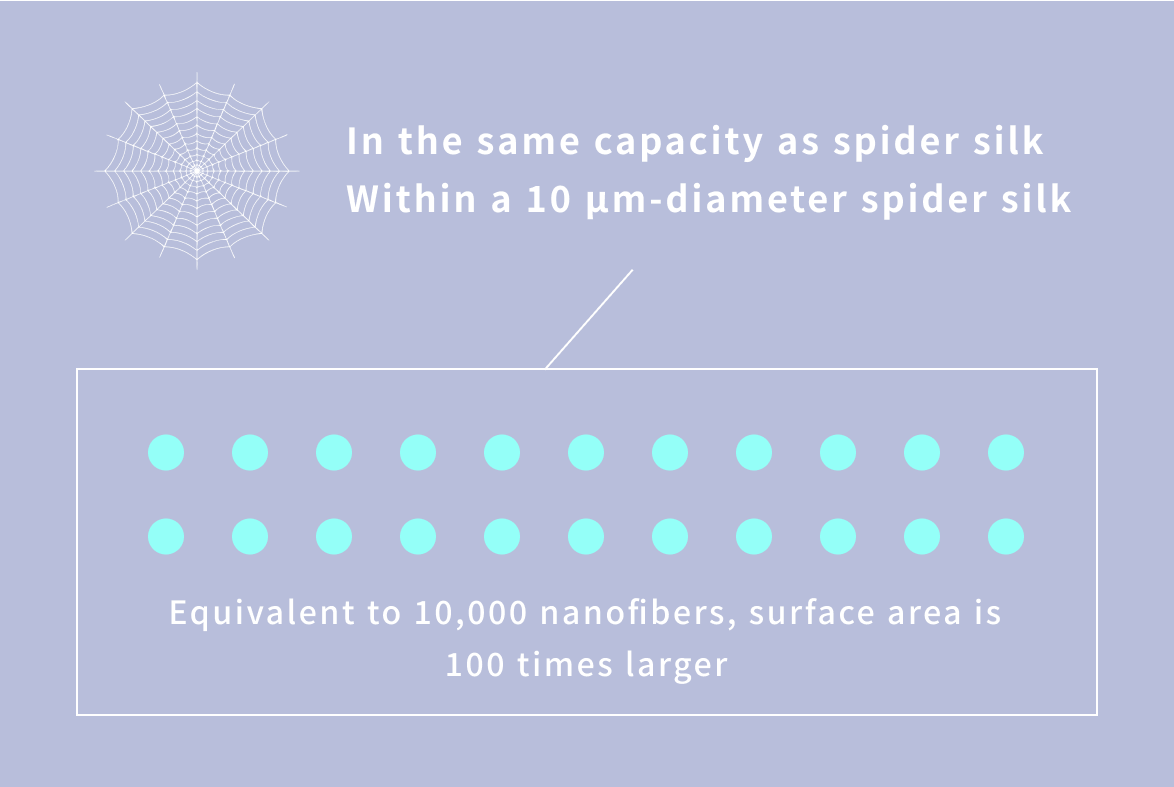

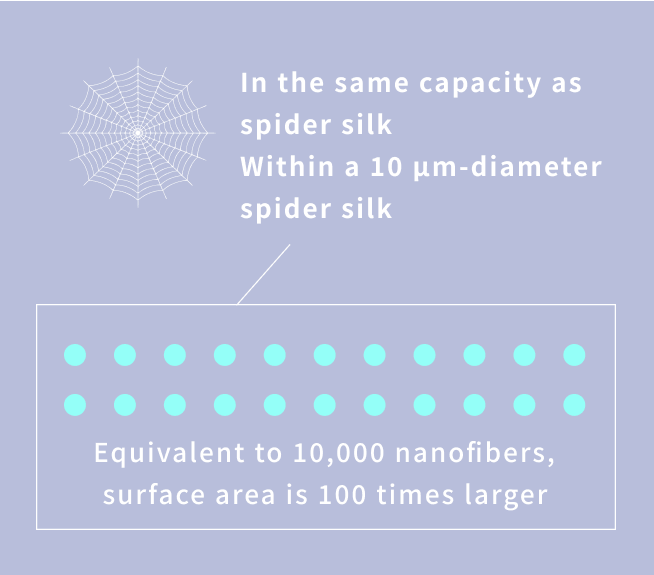

As the fibers become finer, the specific surface area per unit weight increases dramatically, enhancing adsorption properties and molecular recognition. This makes them promising for applications such as biofilters and fuel cell electrodes.

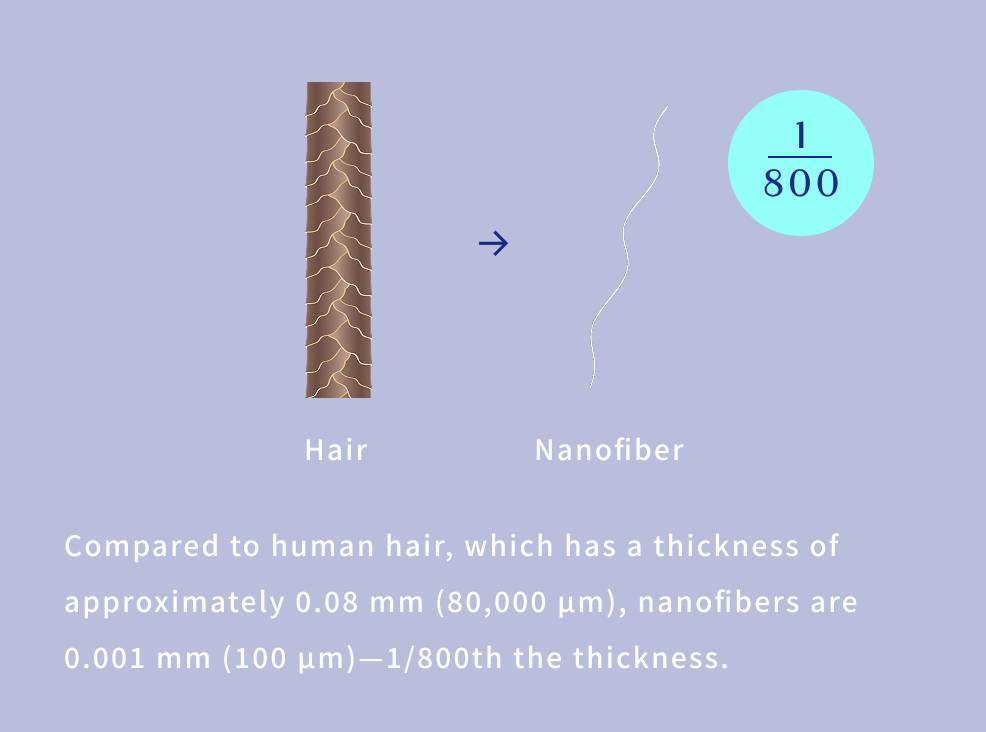

Nanofiber 100 nm < Spider Silk 10 μm, Silk Thread 25 μm, Human Hair 100 μm

The fineness of nanofibers is 1/100 that of spider silk, 1/250 that of silk thread, and 1/1000 that of human hair.

In the same volume as a 10 μm-diameter spider silk, approximately 10,000 nanofibers (100 nm) can fit, increasing the surface area by 100 times.

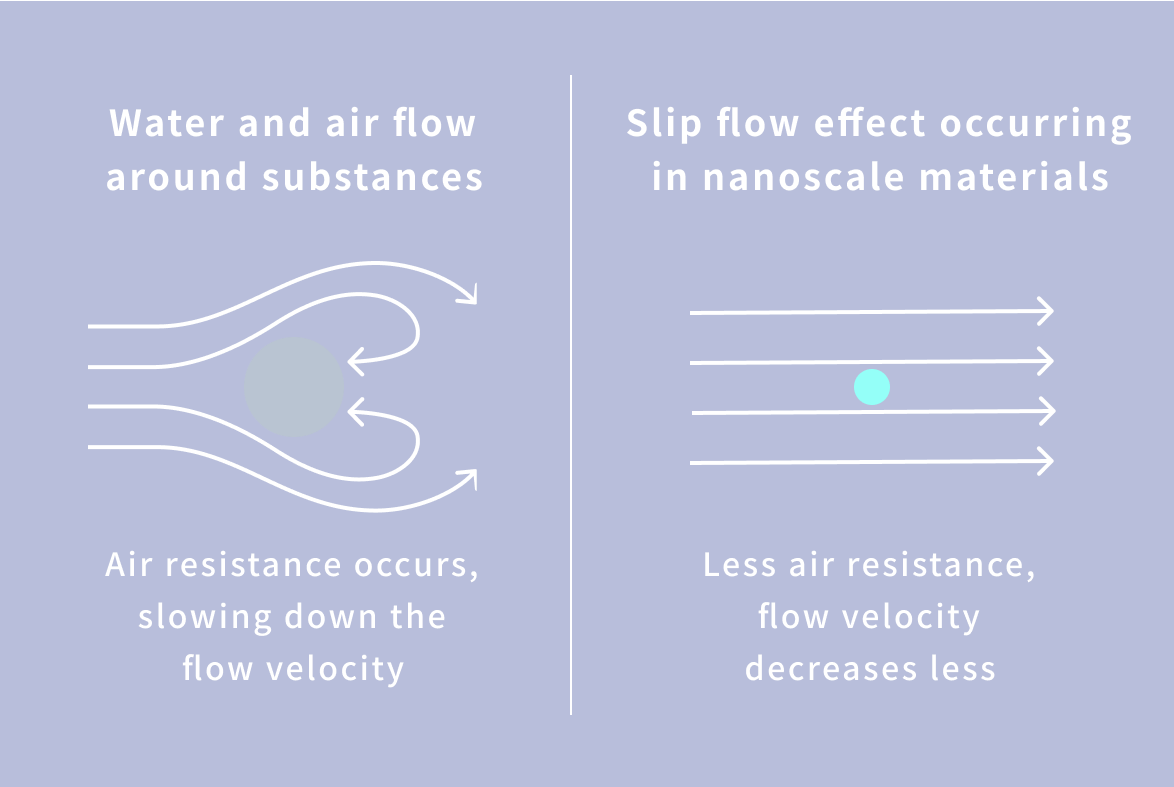

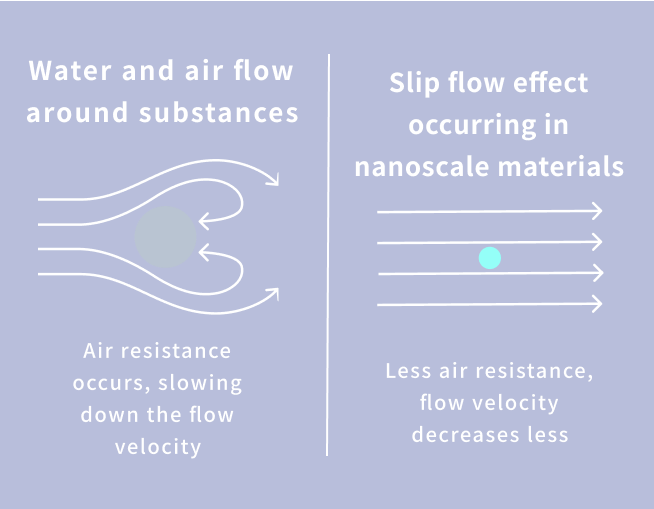

Effects of nanoscale size

The nanoscale fineness of the fibers exhibits fluid dynamic and optical properties. As a result, they enable the creation of high-performance filters with high collection efficiency even under low (pressure) loss conditions, and can also be applied to highly transparent devices such as electronic paper.

Generally, the flow of air and water slows down as it approaches an object, creating air resistance. However, for nanoscale materials (150 nm or smaller), a phenomenon called the "slip flow effect" occurs, which is said to reduce the tendency for flow velocity to decrease.

Microparticles collected by ultrafine fibers

Nanofibers can capture viruses, pollen, and even incense smoke

A demonstration experiment using a nanofilter on an air conditioner filter confirmed that incense smoke was effectively captured and accumulated on the filter.

Applications of Nanofibers

Nanofibers open up new possibilities in product development

Medical field

Nanofibers are used as scaffolds for artificial blood vessels, regenerative medical materials, and wound dressings, promoting cell growth and tissue regeneration. With their antibacterial properties and drug release capabilities, nanofibers also contribute to infection prevention and enhanced therapeutic effects.

Filter industry

The development of high-performance filters capable of capturing particles even smaller than PM2.5 has made a significant contribution to the environmental technology field. Additionally, applications in industry are steadily expanding, including clean filters for semiconductor manufacturing, quality control in food production, and sterile filters for medical use.

Energy sector

Nanofibers are expected to contribute to the enhancement and longer lifespan of batteries as electrode materials and fuel cell components, playing a key role in the evolution of energy storage technologies.

Textile Industry

By utilizing nanofibers, it has become possible to develop incredibly lightweight cold-weather clothing and functional wear that remains comfortable even when sweating. Particularly noteworthy is the smart textile with sensor functions. It is now possible to add new value to textiles, such as sportswear for health monitoring and underwear that supports posture.

Automotive Industry

With its lightweight and high-strength properties, nanofibers are used in interior materials and filters that contribute to improving vehicle fuel efficiency and reducing emissions. Additionally, they are utilized as materials with excellent acoustic properties to enhance the soundproofing inside the vehicle.

Environmental Technology

In wastewater treatment and environmental purification, nanofibers are expected to utilize their adsorption properties to capture heavy metals and harmful substances, thereby improving the efficiency of purification processes.

Innovative Products Realized

PU Resin (Polyurethane)

It is a unique material that allows for flexible adjustment of both flexibility and hardness. By using PU, it is possible to develop masks with excellent breathability and reliable filtration effects, as well as next-generation band-aids that are gentle on wounds.

Polyethersulfone

It is a high-performance material with excellent heat resistance and chemical stability. In particular, it demonstrates outstanding performance as a hollow fiber membrane for water treatment and is used in industrial products such as electrical and electronic components, automotive parts, industrial machinery parts, medical devices, food processing equipment, and aircraft.

Natural Rubber

A highly flexible and stretchable material, making it ideal for applications requiring waterproof properties or elasticity. It is used in products such as medical gloves and specialized rubber items.

PVA Resin / Polyvinyl Alcohol

A water-soluble and environmentally friendly material gaining attention. It is used in films, adhesives, and flexible products. Its biodegradable properties contribute to reducing environmental impact.

PEO Resin / Polyethylene Oxide

A high-polymer material with excellent flexibility and hydrophilicity, used in medical products and specialized coatings. Its biodegradability is particularly noteworthy, making it ideal for environmentally friendly products.

PEG Resin / Polyethylene Glycol

With high hydrophilicity and biocompatibility, it is widely used in cosmetics and medical applications. It is a suitable material for ointment bases and drug delivery systems.

PPE Resin / Polyphenylene Ether

A material with excellent heat resistance, chemical resistance, and dimensional stability, making it ideal for products requiring electrical insulation and high-performance engineering applications.

PVB Resin / Polyvinyl Butyral

With high transparency and adhesion, it is used in automotive glass and architectural films. It also offers excellent durability and stability.

Polyarylate Resin

A material with outstanding heat resistance and UV resistance, making it ideal for optical applications and electronic components. Despite being lightweight, it has high strength, making it widely used in specialized products.

Additionally, materials such as chitosan, titanium oxide, and zinc oxide can also be utilized.

※ Carbon, PP, PET, and PE can be processed separately using our specialized equipment, but they require special development. (Patent registered)

The example of applications of Nanofibers

Diaphragm Performance Testing

We have integrated nanofibers into the diaphragm, the core component that generates sound in speakers. This innovation enables louder, clearer, and more dynamic sound quality. It enhances high-frequency reproduction while reducing noise around 3kHz. Additionally, it can be incorporated into lightweight, thin, and compact products, making it applicable to various types of speakers. The world's first nanofiber diaphragm delivers an unprecedented level of high-quality sound.

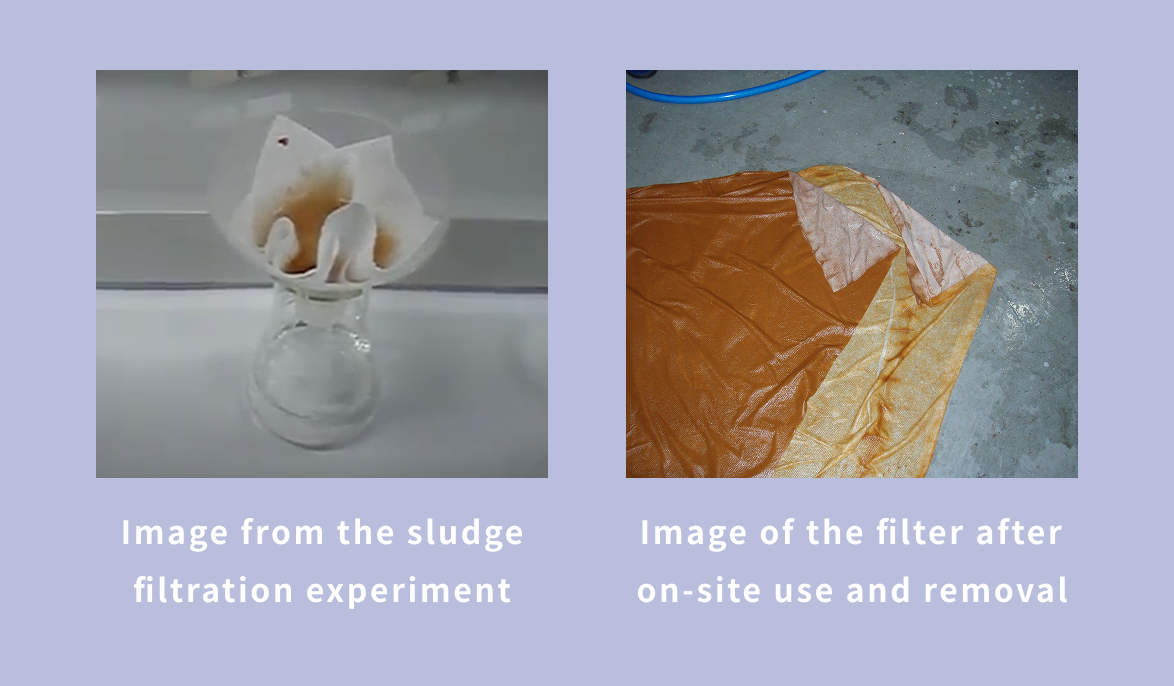

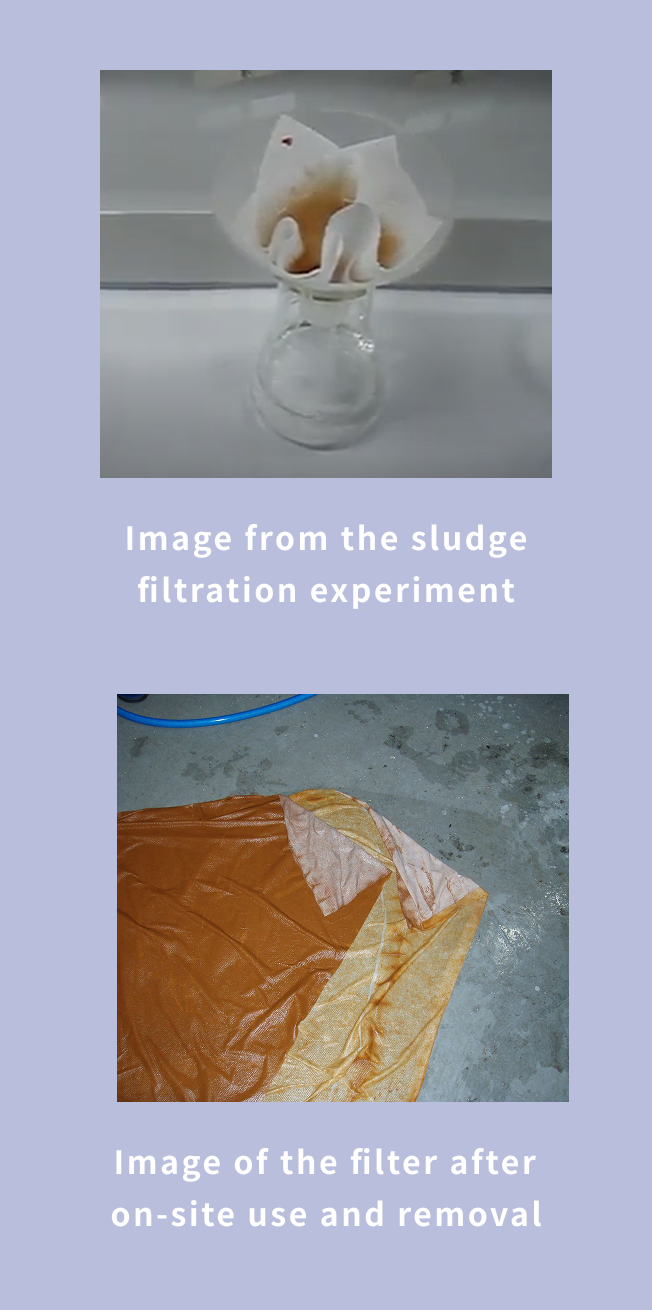

Sludge Filtration Experiment

We conducted a sludge filtration experiment using a nanofiber-based filter. As a result, the water became clear and odor-free. While not suitable for drinking, it has potential for reuse in agricultural irrigation or as bathwater. The photos below show the removal of the nanofiber filter material on-site after the filtration experiment. A significant amount of dirt can be seen attached to the filter.