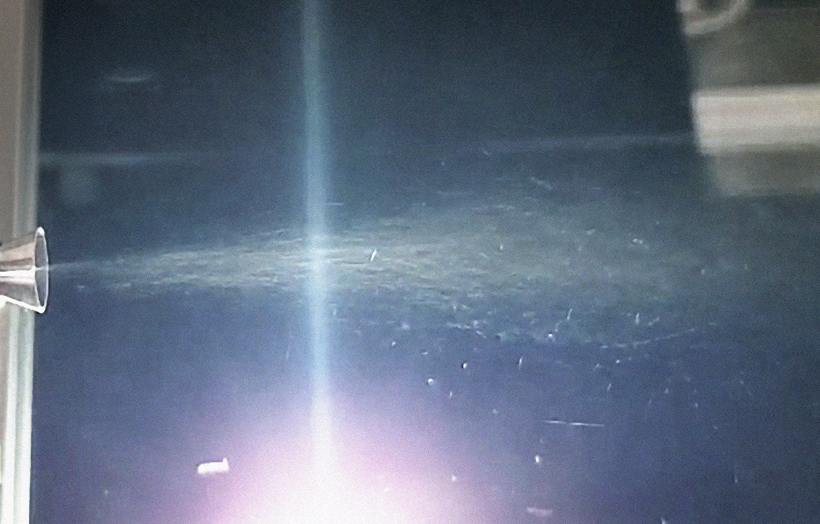

We dissolve resin in an organic solvent and, using our proprietary e‑AFD and AFD methods, extrude the polymer in fiber form. By combining fiber extrusion, conveyance, and drying in a single step, we efficiently produce high-performance nanofibers.

To prevent explosion risks, the solvent‑laden exhaust is diluted with fresh air via exhaust‑system fans to keep solvent concentration below 2,000 ppm.

This diluted exhaust stream is directed toward the nanofiber collection chamber for controlled dispersion.”